JED laboratory extruders are designed specifically for laboratory environments, primarily used for polymer material research, formulation testing, sample preparation, and small-batch pelletizing. Their core advantages lie in their compact size, high precision, and ease of operation, making them ideal for R&D applications in universities, enterprises, and research institutes. The following is a summary of key information:

I. Extruder Types and Features

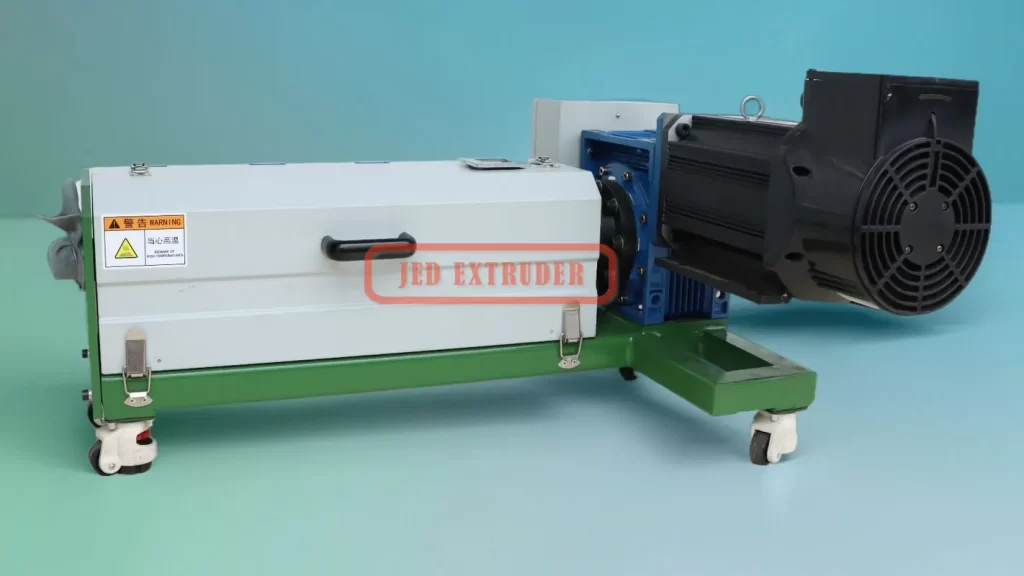

Single-screw extruders: Compact and easy to operate, they are suitable for extrusion experiments with general-purpose plastics (such as PE or PP). They offer uniform feeding, precise temperature control, and stable discharge, making them easy for beginners to quickly learn and maintain. They are also easy to clean and ideal for high-frequency laboratory experiments.

Twin-screw extruders: Commonly used for complex compounding requirements, such as polymer modification and pelletizing. Their smaller screw diameter reduces material consumption and supports water cooling, ensuring uniform, smooth pellets.

II. Core Applications

Polymer plastics research (such as formulation development and performance testing).

Small-batch sample preparation and pelletizing (such as the molding of modified pellets or transparent formulations). Material compounding experiments (twin-screw versions are suitable for challenging tasks, such as TPU or PEEK modification).

Third, choose JED products to ensure equipment stability and after-sales service:

Single-screw extruder:

Small laboratory single-screw extruder: Directly shipped from Zhejiang, China, with high cost-effectiveness, suitable for testing materials such as PE/PP.

Fourth, Selection Recommendations

When purchasing, pay attention to key components: screw speed (affects production capacity and plasticizing effect; modern equipment can reach speeds of over 100-120 rpm), water jacket temperature control (to avoid premature softening or excessive resistance), and reducer design (to ensure high torque capacity). Prioritize models with a screw diameter that matches the experimental specifications.

Φ20/28 Extruder

Screw Diameter: Φ20

Aspect Ratio: 28:1

Drive Motor Power (Domestic Servo Motor): 3.0 kW

Barrel Heating Zones: 3 Zones x 0.7 kW/220V

Rated Screw Speed: 75 rpm

Maximum Output: Approximately 5 kg/h

The screw and barrel are made of high-quality 38CrMoAlA, with a surface nitriding depth of 0.3-0.6mm. The screw structure is suitable for PP and PET extrusion.

1) The motor uses a domestic servo motor, and the reduction gearbox uses an NMRV series.

2) The barrel is heated by a ceramic heating ring, with a heating temperature from room temperature to 30°C.

3) The loading area has a tap water cooling device.

4) The temperature sensor uses a PT100.

5) The protective cover is made of Q235 with insulation.

6) Extruder head center height 210mm, Equipment color: To be determined

7) Spare parts: One heater, one platinum resistor, and one set of screw disassembly and assembly tools.

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

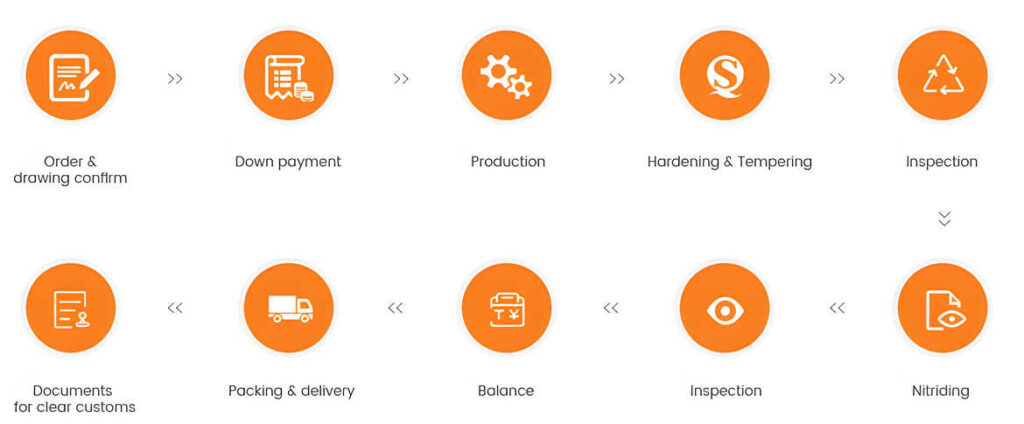

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.