injection molding screw

Specification

injection molding screw Specification parameter

| Amount of injection (g) | Screw diameter*length (mm) | Barrel diameter *length (mm) | Amount of injection (g) | Screw diameter *length (mm) | Barrel diameter*length (mm) |

| 30-90 | Φ30*90 | Φ85*860 | 800-1250 | Φ75*1825 | Φ170*1725 |

| 60-125 | Φ35*910 | Φ85*860 | 1000-1500 | Φ80*2000 | Φ180*1805 |

| 100-150 | Φ38*935 | Φ95*900 | 1250-2000 | Φ85*2300 | Φ190*1900 |

| 125-160 | Φ40*980 | Φ95*910 | 2000-3000 | Φ90*2700 | Φ210*2000 |

| 125-300 | Φ42*1030 | Φ105*8880 | 2500-5000 | Φ100*2600 | Φ230*2405 |

| 250-400 | Φ45*1210 | Φ115*1165 | 3000-6000 | Φ110*2600 | Φ256*2590 |

| 300-500 | Φ50*1300 | Φ125*1260 | 4000-10000 | Φ120*2800 | Φ256*2800 |

| 450-600 | Φ55*1335 | Φ130*1320 | 6000-8000 | Φ130*3010 | Φ256*2970 |

| 500-700 | Φ56*1350 | Φ130*1350 | 8000-10000 | Φ145*3010 | Φ256*3200 |

| 500-700 | Φ60*1380 | Φ140*1350 | 10000-15000 | Φ160*3500 | Φ270*3200 |

| 650-800 | Φ65*1415 | Φ150*1420 | 13000-25000 | Φ170*3415 | Φ317*3380 |

| 700-1000 | Φ70*1790 | Φ160*1685 |

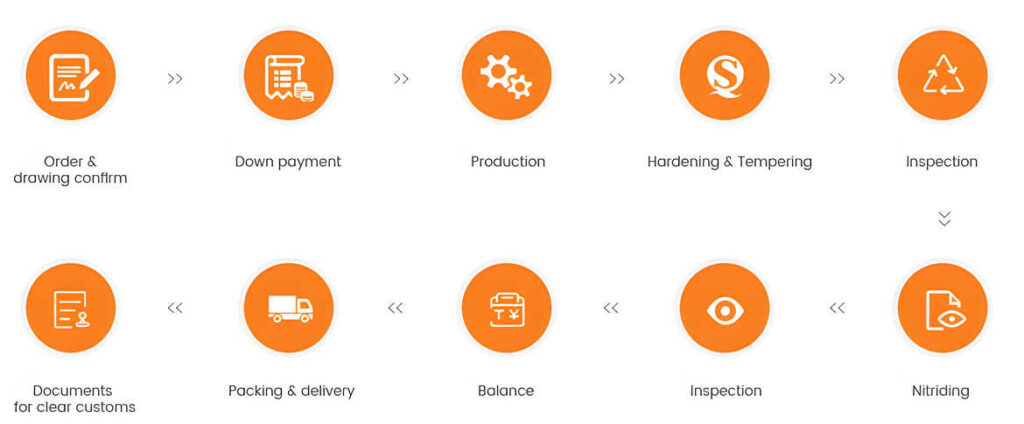

| Production Flow |

Blanking ->Punching ->Rough turning ->Hardening & Tempering ->Finish turning ->Rough Milling ->Finish Milling ->Make grooves for bimetallic ->Bimetallic by PTA ->Rough Grinding ->Rough polishing ->Make splines or Keys ->Nitriding ->Finish Grinding ->Polishing ->Packing & Delivery

Blanking ->Punching ->Rough turning ->Rough Boring ->Hardening&Tempering ->Finish Boring(0.4-0.8mm) ->Make grooves for bimetallic ->Bimetallic by PTA ->Finish Grinding ->Finish turning ->Milling the feeding hole & exhausting holes ->Nitriding ->Make other small holes,thermometer hole,location hole->Grinding surface of feeding hole & exhausting hole ->Polishing ->Packing & Delivery

| Product advantages |

The company has various high-precision product-specific equipment to ensure that product quality continues to improve steadily and continuously, and sincerely provide customers with excellent products and high-quality services.

The company mainly produces various high-precision screws, melt barrels and other plastic machine parts. At the same time, it is also committed to developing screws with higher requirements to meet the needs of the majority of users. Produce first-class products with professionalism.

The company has internationally advanced screw and barrel surface treatment methods and equipment, such as: imported supersonic surface spraying, electroplating, surface high-frequency or medium-frequency quenching, vacuum quenching, nitriding, etc., to meet the needs of different uses.

A professional R&D team is the key to winning the market. People-oriented, constantly seeking new science and technology. Develop more high-quality and fashionable products, introduce international production equipment and scientific and modern management systems, and closely follow the pulse of the times. Whether in technology or design, it maintains a good advantage.

| After-sales service |

While achieving achievements and honors in production, R&D, and innovation, the company has always adhered to the people-oriented approach and continued to invest large amounts of money in the purchase and upgrade of production safety facilities and equipment and employee training. It attaches importance to production without forgetting safety and always rings the alarm bell of “no matter how busy production is, never forget safety.”

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.