Specification:PX-φ45/2-φ150/2

L/D:18~40

Application:

PVC profile(Door & window) / WPC(PVC,PE) / PVC foam board / PVC pipe / PVC compound etc

Functionality & application:

1. Application: PVC

2. Production output: 300kg/h~450kh/h

3. Lifetime: 20,000 hours

( Specification ):

| Φ60/2 | Φ65/2 | Φ70/2 | Φ75/2 | Φ80/2 | Φ85/2 | Φ90/2 | Φ93/2 | Φ100/2 | Φ105/2 |

| Φ115/2 | Φ120/2 | Φ125/2 | Φ130/2 | Φ140/2 | Φ150/2 | Φ160/2 | Φ170/2 | Φ180/2 | Φ190/2 |

| Φ200/2 | Φ250/2 |

For good plasticizing effect, we have different design of screw barrel to meet customer’s demand.

Gradual type, mutant type, wave type, barrier type, double screen type, shunt type, separation type, exhaust type, pin type, mixed type, double-head type, three-head type, multi head type etc.

Scope of application: WPC PVC. WPC PE, Super high molecular sheet, 1/2 high Calcium buckle, 50-400 high Calcium pipe, 50-300 high Calcium Profile, soft PVC sheet, XPS-PVC etc.

PP、PE、ABS、PVC, raw material, pelletzing, pipe, profile, sheet etc.

Screw & Barrel use material

| Raw material | The finished product processing requirments |

| 38CrMoAIA, SACM645 | Nitriding treatment |

| Cr12MoV, Cr12 | Alloy steel |

| 38CrMoAIA, SACM645, 40Cr, AISI4140, 42CrMo | Bimetallic of the inner hole centrifugal casting |

| GHII3 | Nature hard after high temperature |

Technical parameter

| Model | Motor power (kw) | Screw dia. (mm) | L/D | Screw rotation speed (rpm) | PVC Production (kg/h) |

| QY75 | 45 | 75 | 26-36 | 45 | 220-350 |

| QY90 | 55 | 90 | 26-36 | 45 | 280-460 |

| QY110 | 75 | 110 | 26-36 | 45 | 350-650 |

| QY120 | 110 | 120 | 26-36 | 45 | 500-80 |

| QY130 | 132 | 130 | 26-36 | 45 | 680-1000 |

The production of high profile PVC, PVC pipe with large bore, and WPC extrusion requirments of research and development, with the small shear rate, soft compressed, and the material is resist to compose, the good plasticzing, high output, wide application range, high reliability.

Confirm the material being processed, HRC, value, quantity, according to drawings and samples requires grinding forming angle and tolerance. Mass production is now only, can completely replace the international first-class products, is highly cost-effective.

With the advanced integrated production system, and all kinds of precision technology production and processing capacity, it can realize high efficiency, and low cost application.

From the six axis, seven axis CNC machining high-grade products to the three shaft, four axis production middle grade products, different levels of quality and price. Professional alternative to first-class industrial products, special, non-standard, special-shaped, new products in large quantities, the high cost of research and development, production and processing, according to drawings and samples to improve the design, can greatly reduce the comprehensive cost.

Please provide samples or requirements about dimensions and tolerances of, semi-finished and finished products, the equipment, equipment value RMB ( to judge its rigidity and jumping), the monthly consumption quantity, the current screw are using HRC and so on.

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

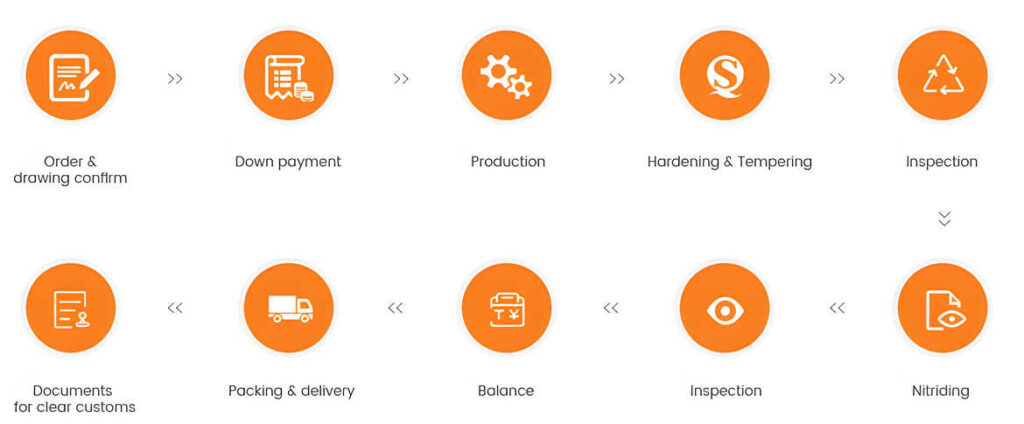

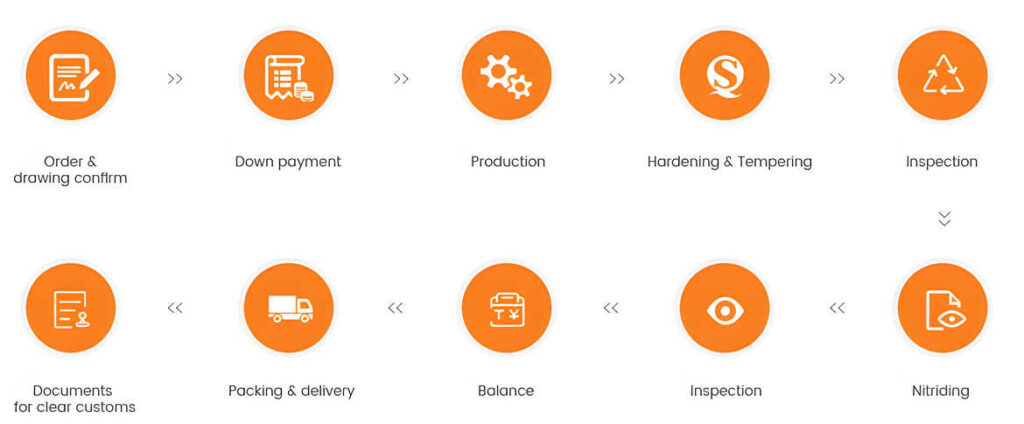

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.