The screw of a sugar extruder is a key component in candy production. Its operating principle and design are similar to those of a plastic extruder, but it is optimized for the characteristics of food ingredients such as sugar paste. The following are key technical details:

Feed Section: Sugar paste enters the screw feed section through a metered injection system and is conveyed forward by the screw’s screw threads.

Compression and Plasticization: The screw’s rotation generates shear forces, uniformly plasticizing the sugar paste under high pressure while removing entrained air.

Forming Section: The molten sugar paste is extruded through the die head, cooled and shaped, and then demolded to form a continuous product (such as bonbons or tubes).

Screw Design: A single screw is typically used, divided into a feed section, a compression section, and a homogenizing section. The screw pitch and flute depth are adjusted according to the viscosity of the sugar paste.

Die Adaptation: The die head is equipped with a bell-shaped die hole for easy demolding and consistent product specifications. Temperature Control System: External heating and cooling systems precisely control the temperature of the massecuite to prevent burning or over-softening.

Efficient and Continuous Production: Compared to traditional processes, extrusion technology shortens the process and improves raw material utilization, making it suitable for large-scale candy production.

Product Diversity: Can produce a variety of candies, including puffed, filled, and multi-layered ones, such as ready-to-eat cereals or decorative syrups.

Cleaning Requirements: The screw must be regularly disassembled to remove residual massecuite and prevent microbial growth.

Wear Inspection: Use a micrometer to measure the dimensions of the threaded components and promptly replace any cracked or severely worn parts.

Note: Food-grade screws must meet hygienic standards and are typically made of stainless steel or a wear-resistant alloy with a polished surface to reduce massecuite adhesion.

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

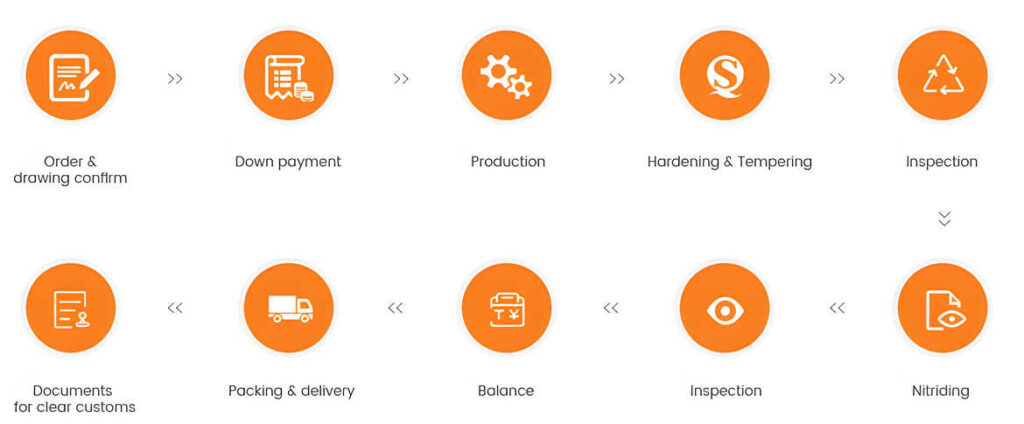

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.