Introduction:

The screw is made of high-quality alloy steel, which has been precisely processed, tempered and nitrided, and has the best hardness and corrosion resistance. The specially designed screw is equipped with a forced conveying bushing, with a reasonable structure, stable performance, good plasticization, high output, low energy consumption, and clear stratification. It is an ideal choice for producing high-strength, aging-resistant, drip-free, light-transmitting, heat-insulating and other multifunctional films.

Application areas:

I) Polyethylene film

A) Ordinary polyethylene film, heat shrinkable packaging film, air cushion film, cling film (LDPE according to melt index), used for ground film, rice seedling film, daily packaging bags, food packaging film, etc.;

B) Heavy packaging film (LDPE+LLDPE) used for heavy packaging bags

C) Greenhouse film (ordinary greenhouse film LDPE, enhanced greenhouse film LDPE+LLDPE)

II) Polypropylene film

A) Blown packaging film (IPP film)

B) Extrusion cast film (CPP film)

C) Biphasic stretch film (BOPP film)

III) Polyvinyl chloride film

A) Soft polyvinyl chloride blown film

B) Anti-rust shrink film

C) Rigid polyvinyl chloride transparent packaging film (PVC cellophane)

Specifications:

Screw diameter: φ45-φ150

Aspect ratio: 25-32

Product type:

For different plastic ratios, screws can be selected: ordinary type, pin type, barrier type, separation type, corrugated type, etc.

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

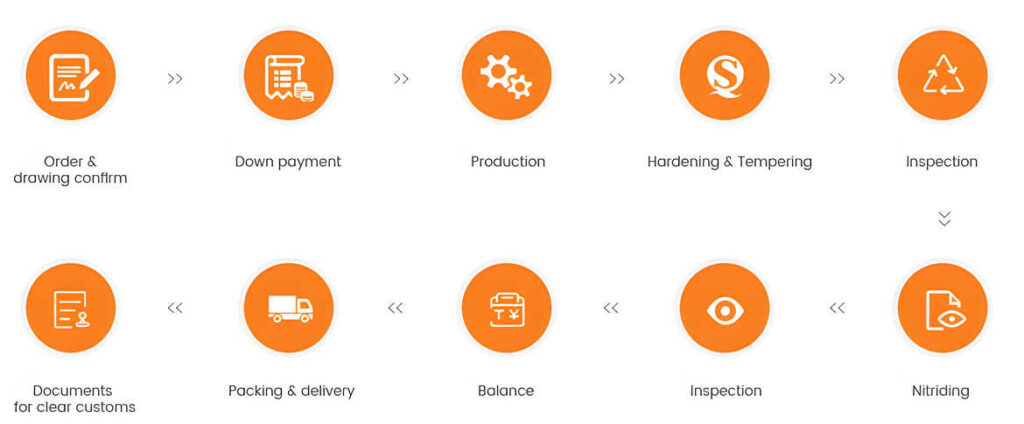

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.