Ice maker blade is one of the core components of the flake ice maker, mainly used to cut the ice layer formed on the inner wall of the evaporator, peel off and break the ice cubes into specific shapes of flake ice. Its core features and technical points are as follows:

1、 Core functions and working principles

Ice cutting

The ice blade is fixed on the spindle and scrapes the ice layer on the inner wall of the evaporator by low-speed rotation. The thickness of the ice layer is usually controlled at around 2mm. After cutting, it forms a thin sheet of ice and slides down to the storage refrigerator by gravity.

Collaborative system operation

The ice making process is completed by coordinating the ice cutter with the evaporator, circulating water pump, and spindle drive system. The water quickly cools and freezes on the surface of the evaporator, and the unfrozen water flows back to the water tank through the flow channel for recycling.

2、 Ice blade material and structural parameters

Common materials

Ice skates are often made of stainless steel materials (such as SUS304, SUS316) to ensure corrosion resistance and stability in low-temperature environments.

Key design parameters

Blade precision: The tip width is 0.4-0.5mm, ensuring uniform thickness of the ice sheet.

Tolerance control: The bearing position aperture tolerance is ≤ 0.01mm, and the concentricity at both ends is < 0.04mm to ensure rotational stability.

Spiral direction: mainly designed for right-hand rotation, suitable for different ice maker models.

3、 Classification and adaptation scenarios

Blade type

Spiral blade: suitable for continuous cutting, with high ice crushing efficiency, commonly used in medium and large ice making equipment.

Rake blade: suitable for specific ice peeling scenarios, with a simplified structure.

Application Fields

Including preservation of aquatic products, low-temperature storage in laboratories, chemical cooling, etc., it is necessary to adapt to the scene requirements according to the specifications of ice flakes (such as thickness and contact area).

4、 Maintenance and Performance Optimization

Drive system matching

Ice skates are driven by a reduction motor or gear set, and the speed needs to be synchronized with the freezing rate; Some high-end models use fully enclosed compressors to extend the motor life (such as the Panasonic laboratory ice maker motor life of 18000 hours).

Maintenance points

Regularly check the blade wear and bearing lubrication status.

Clean up residual ice residue to avoid lagging or decreased refrigeration efficiency

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

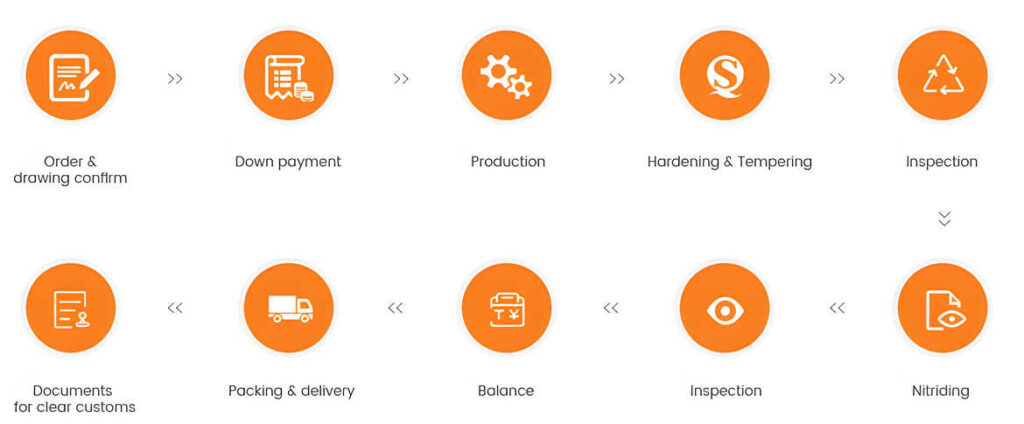

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.