Our screws are used in rubber injection machines. As an efficient and stable molding equipment, rubber injection machines are applied in multiple industries, as follows:

1、 Automotive industry

Producing key components such as automotive tires, seals, shock absorbers, etc,

Manufacturing engine seals and shock pads that are resistant to high temperatures and corrosion.

2、 Electronic industry

Used for the production of electrical insulation parts, electronic equipment seals, and insulators;

The silicone rubber injection machine can meet the manufacturing of electronic components with special requirements such as high temperature resistance and insulation.

3、 Medical industry

Production of disposable or durable medical products such as medical grade silicone tubing and medical gloves;

Manufacturing high-precision medical equipment seals and biocompatible rubber components.

4、 Industrial and labor protection fields

Large scale production of mining rain boots and labor protection shoe soles;

Manufacturing shock-absorbing pads, industrial seals, high difficulty thick or thin-walled shoe soles, etc.

5、 Sports equipment

Production of rubber inner and outer shells for sports equipment such as basketball and football;

Customized sports shoe soles and high elasticity sports equipment accessories.

6、 Other fields

Shock absorbing components and waterproof seals used in the home appliance and construction industries;

Production of complex structures or colored rubber products through multi-color injection technology.

Note: Some new devices, such as vacuum dual-mode synchronous injection machines, have further improved the production efficiency of complex products such as shoe soles by optimizing injection molding reflux technology

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

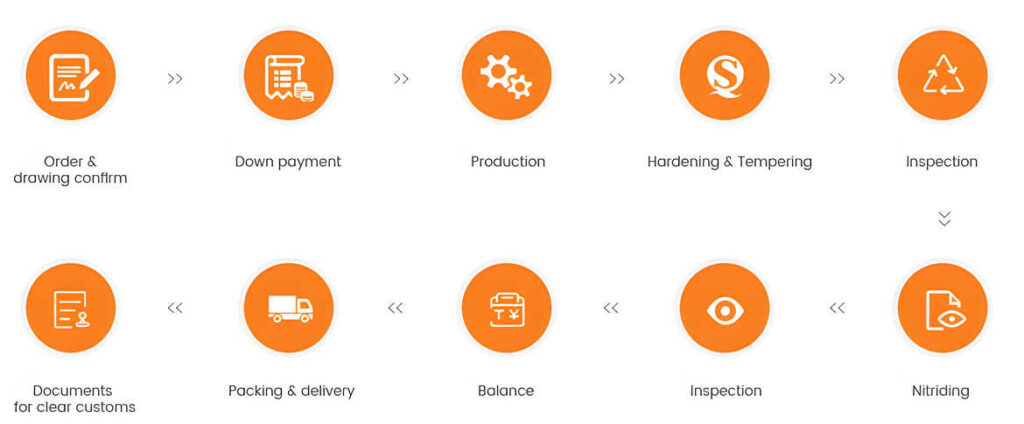

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.